PIEZO TIPS

Click here to view our piezo tips

CLEANING AND STERILIZATION

Piezo tips should remain in the wrench during the complete cleaning, disinfection, and sterilization reprocessing cycle. Clean using ultrasonic cleaner or thermodisinfector. Steam sterilize for at least 4 minutes at 270° F (132°C). Clean, disinfect, inspect, and steam sterilize before each use following the respective equipment manufacturers users instructions. Do not expose to phenols, iodophors, or dry heat sterilization.

REPLACEMENT OF WORN INSERTS AND TIPS

Scaling efficiency can significantly diminish with worn insert tips. Inferior performance and poor water delivery can result from worn, damaged, bent, or altered tips. 1mm wear diminishes 25% efficiency and 2mm wear diminishes 50% efficiency. For optimal scaling efficiency, we recommend checking inserts monthly for signs of wear.

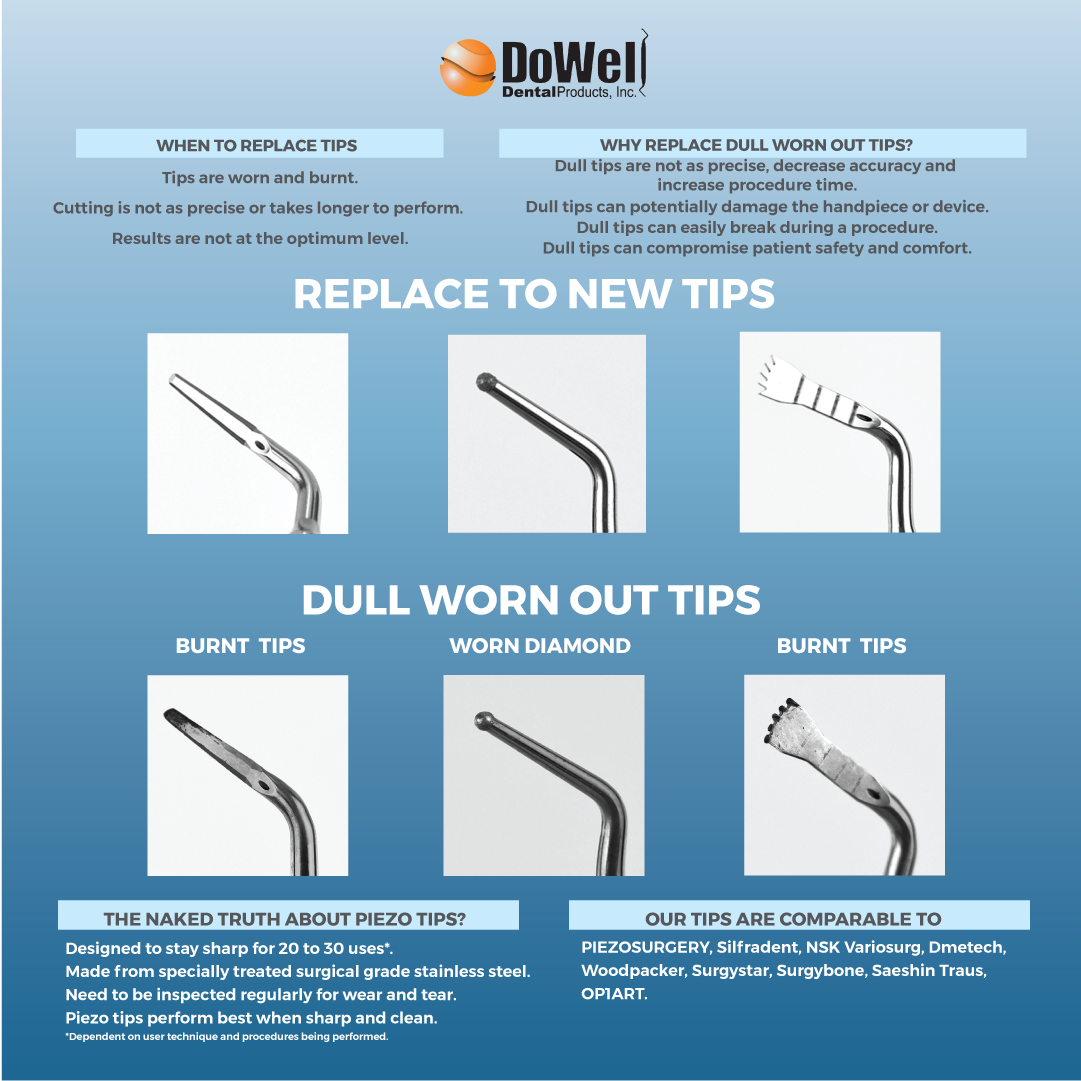

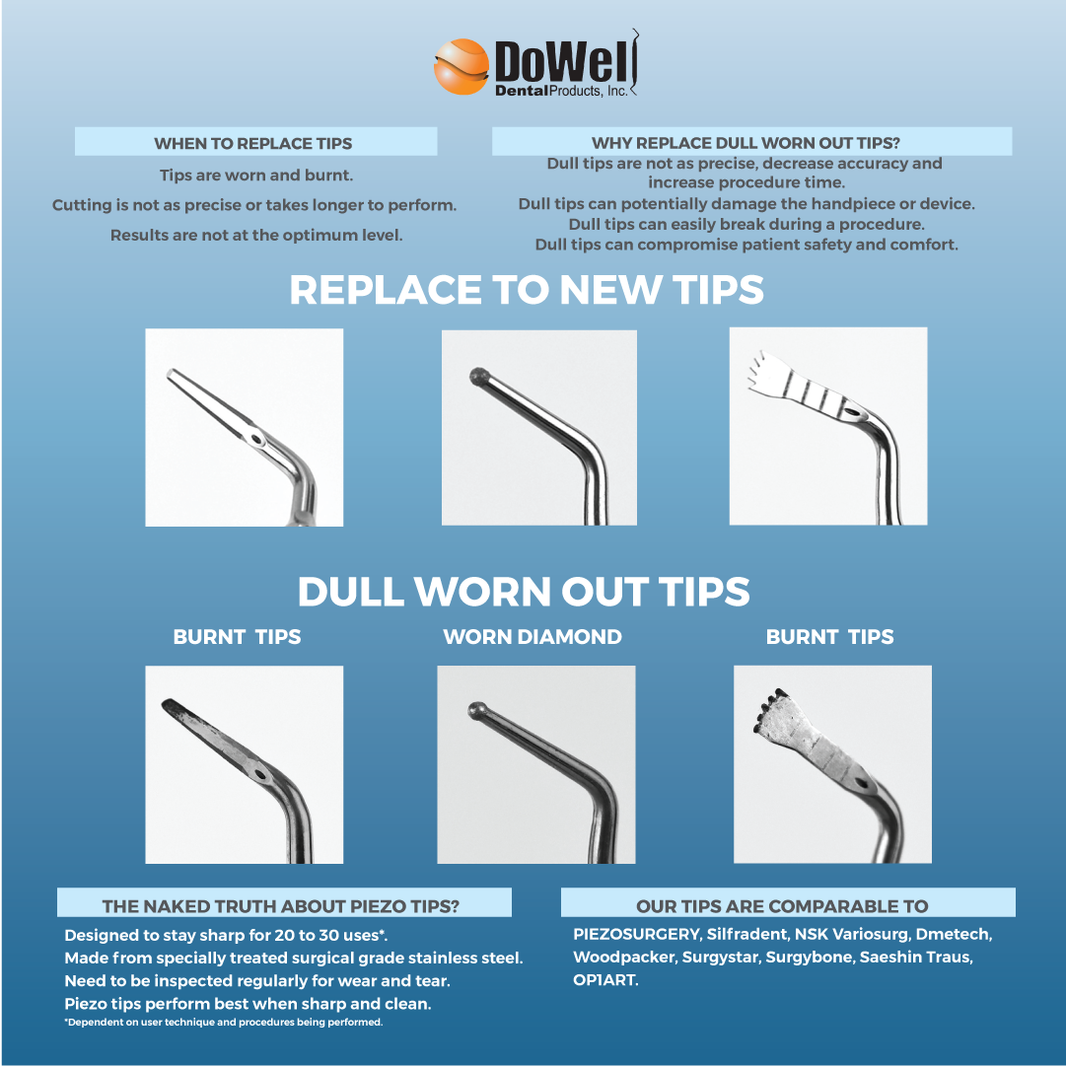

WHEN TO REPLACE TIPS

• Tips are worn and burnt

• Cutting is not as precise or takes longer to perform

• Results are not at the optimum level

WHY REPLACE DULL WORN OUT TIPS?

• Dull tips are not as precise, decrease accuracy, and increase procedure time

• Dull tips can potentially damage the handpiece or device

• Dull tips can easily break during a procedure

• Dull tips can compromise patient safety and comfort

THE TRUTH ABOUT PIEZO TIPS

• Designed to stary sharp for 20 to 30 uses*

• Made from specially treated surgical grade stainless steel

• Need to be inspected regularly for wear and tear

• Piezo tips perform best when sharp and clean

* Dependent on user technique and procedures being performed